They say the only guarantees in life are death and taxes. However, for those running hydraulic equipment the issues inherent with these temperamental systems seem like the third guarantee in life. While it seems like there is simply no solution to the leaks, the over heating, the seal deterioration, the poor response and the pump failures; we are here to tell you differently. Let Royal Oil Co. introduce you to products that will have you back to worrying about only death and taxes again!

Issues with hydraulic systems are so common that most just feel it is “part of running equipment.” However, continue reading and allow us to shed a little bit of light on the common issues, why they occur and why you should change your expectations immediately.

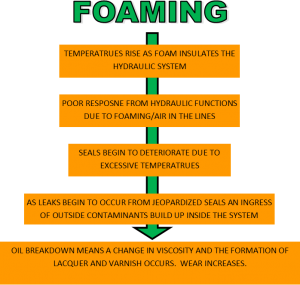

PROBLEM: FOAMING

Let’s begin with the most common issue and touch on all the areas it can impact your hydraulic system. Foaming occurs when cavitation occurs, the collapsing of fluid onto itself. In enclosed systems such as hydraulic systems and gear boxes…this is going to occur. The foam acts as an insulator and this is where the problems begin to pile on top of one another. Click on the flow chart to the right and see the impact of foaming inside your hydraulic system.

issue and touch on all the areas it can impact your hydraulic system. Foaming occurs when cavitation occurs, the collapsing of fluid onto itself. In enclosed systems such as hydraulic systems and gear boxes…this is going to occur. The foam acts as an insulator and this is where the problems begin to pile on top of one another. Click on the flow chart to the right and see the impact of foaming inside your hydraulic system.

ANSWER: NON-FOAM CHEMISTRY

Royal’s ULTRA TORQUE, ROYAL TORQUE, and standard hydraulic oils are built using an industry best non-foaming additive designed to rapidly release and eliminate foaming. By doing this the common issues to the right are eliminated.

PROBLEM: WEAR

Hydraulic pump failure is an all too common occurrence. Many feel it is just part of running hydraulic equipment, however that is simply not the case! Not only is a hydraulic oil designed to transfer power, providing the system with the ability to function; the oil has another primary function. Reducing wear within the system is a critical role for hydraulic fluids and the design of the product directly impacts its ability. Lower grade hydraulic oils contain just enough anti-wear additives to meet the loosest of industry standards, leaving equipment subject to parts failure.

ANSWER: INDUSTRY BEST ANTI-WEAR

Not only does Royal Oil Co.’s Royal Torque contain an industry best anti-wear additive, it is offered in a higher concentration. For years a high level benchmark was set forth by Caterpillar at 900 ppm of zinc. Royal Torque and Ultra Torque provide anti-wear protection at zinc levels of 2000 ppm; more than double the CAT standard.

A common initial response when we introduce Royal Torque goes something like this, “Id like to use a better tractor fluid, but my equipment leaks so bad…” The answer to this is an easy one…”your equipment was not designed to leak oil, your inexpensive standard fluid is the cause of that problem.” As mentioned in the first section of this article…foam causes heat, heat damages seals and when seals are jeopardized oil is lost. However, equally as critical is the ingress of contaminants from the leak points. Leaks will destroy a hydraulic system, often sooner than later.

ANSWER: INDUSTRY BEST ANTI-WEAR

With an industry best non-foaming additive package, Royal Torque reduces foam and provides a massive drop in operating temperatures. This in turn preserves seals and allows them to function better for longer periods. No more leaks!

Leave a Reply